Perfect Speed, Low Motor Noise: A Vinyl Enthusiast’s Dream

MagicQuartz is a system for precise turntable speed control. It delivers perfect speed stability and reduced motor noise. Designed for hi-fi turntables with AC motor, it combines a modular, open-source hardware design with a highly configurable, state-of-the-art microcontroller firmware.

MagicQuartz not only isolates the turntable from mains frequency fluctuations, its signal generation achieves a resolution of 0.0001 Hz, ensuring absolute timing accuracy. With its “Live Quartz Mode”, it can continuously monitor and adjust the speed in real-time.

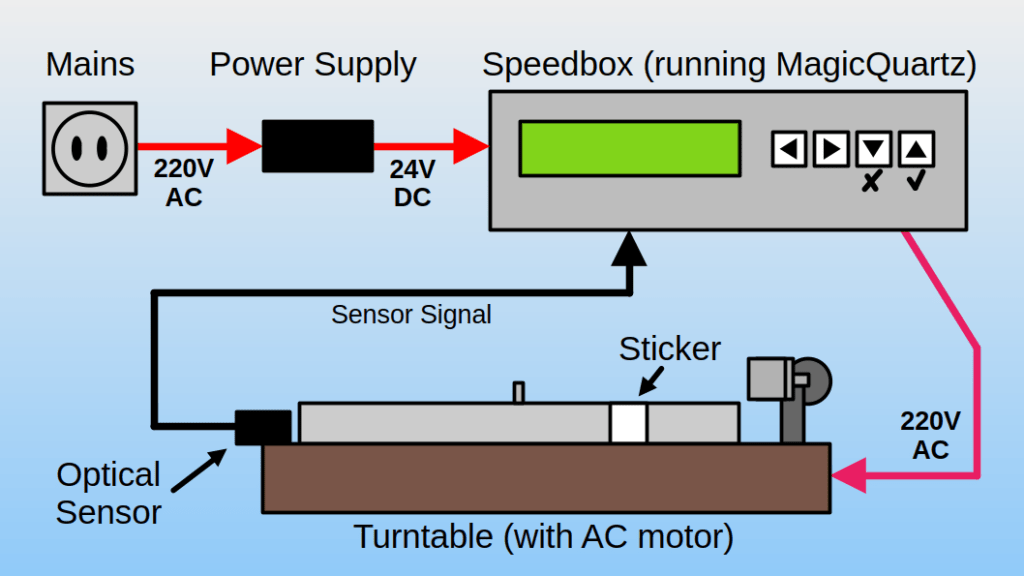

The speedbox measures the current turntable speed using an optical sensor and adjusts the generated AC frequency to achieve perfect playback speed.

The optional automatic voltage reduction minimizes motor noise on turntables with synchronous AC motor, delivering direct-drive-like quietness while preserving the punchiness of your idler or belt-drive.

Your records have never sounded this good — promised!

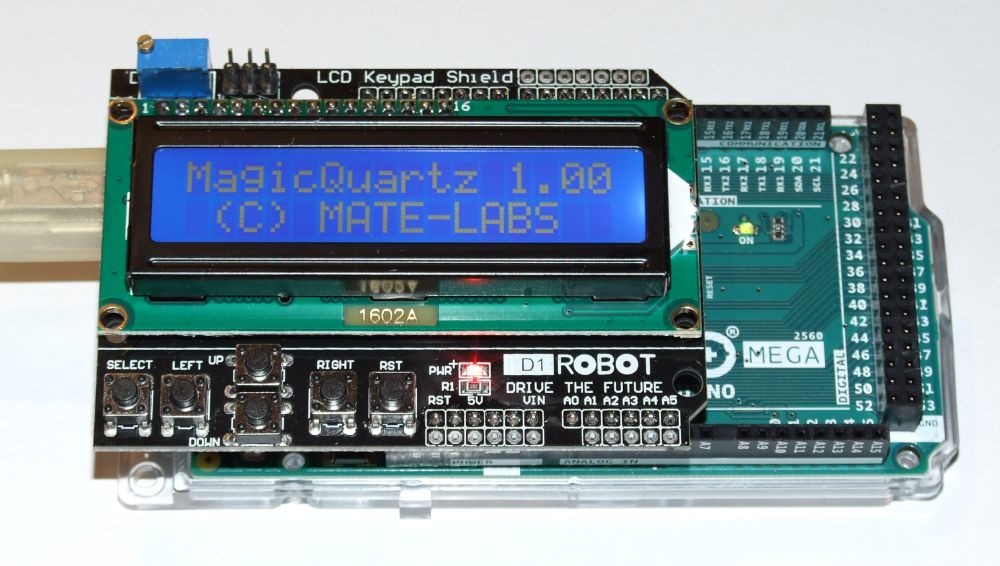

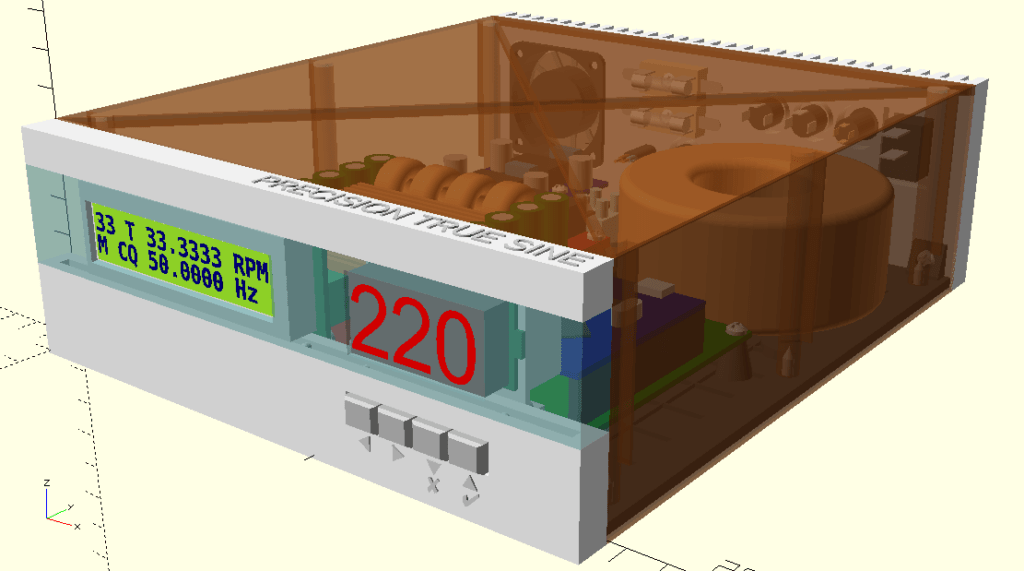

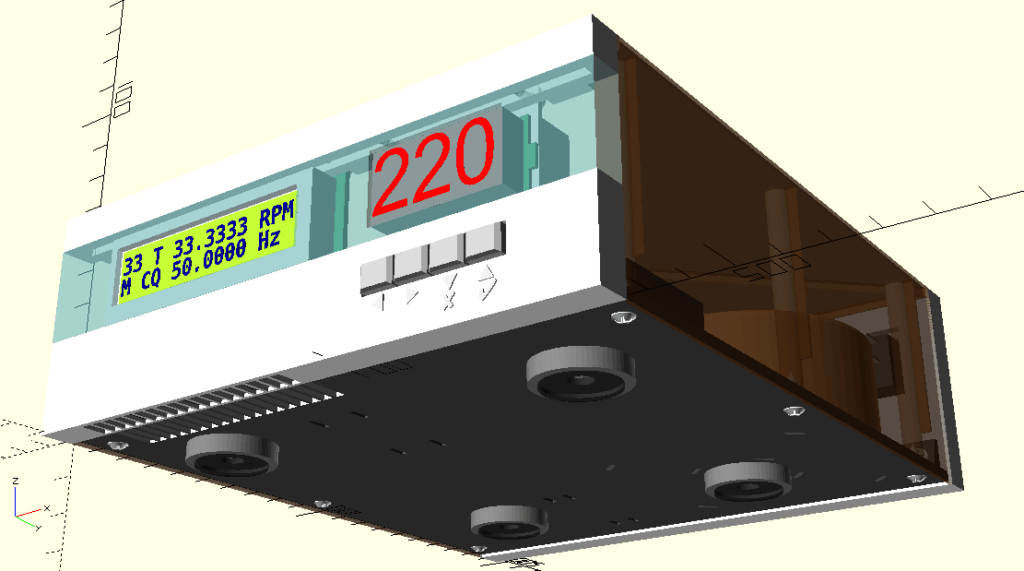

MagicQuartz is aimed at DIY enthusiasts with electronics knowledge and professional hardware developers. The firmware has been developed for the 8-bit AVR microcontroller family from Microchip (formerly Atmel) and can also be used directly on Arduino hardware for prototyping (see image below, left). The easy-to-build, open-source hardware design provides a fully 3D-printable enclosure and electronic circuit (image below, right).

Firmware Features

Smart Turntable Speed Control

- Live Quartz Mode: Automatically monitor and correct turntable speed in real-time.

- Ultra-Precise Timing: Operates at a high temporal resolution of 100 µs (0.0001 Hz).

- Speedbox Function: Switch between 16, 33, 45, and 78 RPM electronically.*

- Intelligent Control: Automatically halts speed corrections when major changes occur (e.g., during auto start/stop functions). Detects and stops control in case of motor failure, broken belt, or idler wheel issues.

- Customizable Settings: Adjust regulation velocity, frequency change limits, and many other (around 40) parameters.

- Voltage Reduction: Optionally reduces AC voltage to minimize motor vibration and noise.*

- Transpose Function: Allows musicians to adjust playback pitch in semitone increments.*

* These specific functions may not work optimally with asynchronous motors. Motors with phase-shifting capacitors may need to be rewired to a two-phase configuration. See documentation/FAQ for details.

True Sine Signal Generation

- Multiple Waveforms: Supports single-phase and dual-phase true sine signal generation with variable phase shift, offering many options for custom inverter designs.

- Hi-Fi Quality: Uses inaudible PWM at 31.250 kHz for hi-fi-grade motor drive.

- High-Resolution: 8 or 9-bit wavetable with 128 samples per sine wave period, scaled via floating-point arithmetic and reproduced at a variable sampling rate.

Advanced Power Management (APM)

- Current Monitoring: Continuously measures inverter load.

- Voltage Correction: Adjusts generated voltage based on inverter load.

- Error Handling: Detects and responds to inverter shutdowns or overloads.

Additional Features

- Automatic Motion Sensor Calibration: Guides the user in positioning the sensor for optimal performance.

- Usage Tracking: Uptime counters track record player usage, helping monitor stylus wear.

- Little Distraction: Resumes its last mode automatically upon startup.

- For Longevity: Flash memory caching and wear leveling to extend lifespan of the microcontroller.

- For Safety & Environment: Configurable auto-standby timers.

High Adaptability to Hardware Designs

- Platform Support: Developed for Microchip’s AVR 8-bit microcontrollers, with a readily available version for the ATmega2560.

- Display Support: Supports 2×16 character LCDs and serial communication (the latter for prototyping).

- Flexible Button Configurations: Works with individual buttons or resistor-network-connected buttons.

- Rapid Prototyping: Additional full compatibility with the Arduino Mega 2560 Rev3 and common LCD keypad shields. The firmware automatically detects on which hardware it is running.

Availability — Get Started NOW!

Already have an Arduino development board with an ATmega2560? Great! Simply visit the Downloads page and get started right away! Also note the extensive, carefully crafted PDF documentation (more than 100 pages), which you can also find there. This YouTube video may also be useful.

Last, but not least: MagicQuartz is proprietary software that requires activation for full functionality. Without activation, it operates in a usable but slightly limited demo mode designed for evaluation and hardware development. Full licenses for personal use are free — you can find out why in the FAQ. To activate a license, simply send me an email: Contact Information

More MagicQuartz Resources

Be sure to also check out these pages to find additional resources:

Another rendering of the MagicQuartz TechDemo, created with OpenSCAD.

History

What initially started as a crazy idea soon developed into the ambitious goal of developing the world’s best speed control for turntables. The project now looks back on over a decade of passionate research and development (admittedly with major breaks in between):

- January 2011: First crude square wave inverter capable of driving a Dual 1219 at 220V/50Hz (image below, top left). Implemented using an Atmel STK 500 and ATmega32. Back then, the firmware was called “MultiQuartz”.

- January 2015: Demonstration of a first turntable speedbox based on the more modern ATmega328P (image below, top right). A specially developed digital sine wave inverter based on an H-bridge was used. MagicQuartz firmware version 0.9.

- 2021-2022: Continued development and porting of the firmware to the ATmega2560 and development of the “MagicQuartz TechDemo” (image below, bottom).

- April 2023: Release of MagicQuartz 1.0, “Phoenix”.